WRSM

A wound-rotor synchronous motor, also known as a slip-ring synchronous motor or externally excited synchronous motor (EESM), is a type of electric motor that combines features of both synchronous motors and wound-rotor induction motors.

Last modified: Jan 01, 2025How It Works

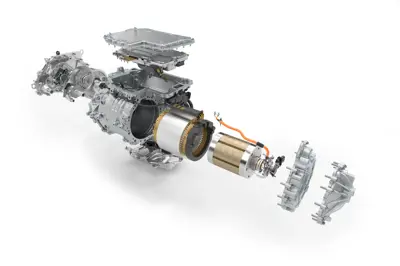

A wound-rotor synchronous motor has a stator similar to that of a synchronous motor, consisting of a laminated iron core with stator windings. However, the rotor of a wound-rotor synchronous motor differs from a conventional synchronous motor.

The rotor winding of a wound-rotor synchronous motor is typically made up of multiple coils of wire, connected to the rotor via slip rings and brushes. The slip rings allow electrical connection to the rotor winding, while the brushes transfer electrical power to and from the rotor.

The motor operates based on the principles of electromagnetism and synchronous motor operation. The stator windings are connected to an AC power supply, creating a rotating magnetic field. The rotor winding is also connected to the power supply through the slip rings and brushes, allowing for variable resistance or impedance to be connected to the rotor winding, which can be used to control motor performance.

The rotor winding is excited with DC current, creating a magnetic field in the rotor. The interaction between the stator's rotating magnetic field and the rotor's magnetic field causes the rotor to rotate in synchronism with the stator's magnetic field, hence the name "synchronous motor."

Currently, BMW, Nissan, and Renault use WRSM motors.

Advantages

Wound-rotor synchronous motors offer several advantages, including:

Variable Speed and Torque Control: The use of slip rings and brushes in the rotor circuit allows for variable resistance or impedance to be connected, enabling control over the motor's speed and torque characteristics. This makes WRSMs suitable for applications requiring precise speed and torque control, such as industrial processes or traction systems in electric trains.

High Efficiency: WRSMs can achieve high efficiency due to their ability to control the rotor circuit impedance, allowing for optimized motor performance under different load conditions.

Higher Power Factor: WRSMs typically have a higher power factor compared to induction motors, improving overall motor efficiency and reducing reactive power demand from the power grid.

No Need for Rare-Earth Materials: WRSMs do not require rare-earth materials, making them more sustainable and cost-effective.

Limitations

Wound-rotor synchronous motors also have some limitations, including:

Complexity: WRSMs are more complex compared to other types of motors, such as induction motors or permanent magnet motors, due to the presence of slip rings, brushes, and rotor windings. This increases the complexity of motor control and maintenance requirements.

Higher Cost: The additional components, such as slip rings and brushes, can increase the cost of WRSMs compared to other motor technologies.

Maintenance Requirements: The presence of slip rings and brushes in the rotor circuit requires regular maintenance, such as cleaning, inspection, and replacement, increasing operating costs and maintenance efforts.