Motors & Drive Units

As the automotive industry rapidly shifts towards electrification, the heart of electric vehicles (EVs) lies in their motors and drive units. With a diverse array of motor types and intricate inverters, understanding the complexities of these components is crucial for comprehending the inner workings of EVs.

In this extensive article, we will take an in-depth look at motors and drive units for electric cars, examining the various motor types commonly used in EVs, exploring the intricacies of the inverter, and delving into the critical role these components play in propelling the future of transportation.

First, we will explain the common principles of electric motors.

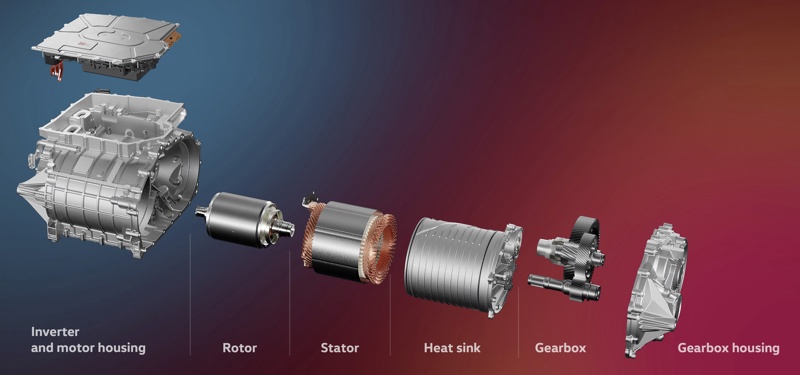

VW Electric drive unit parts.

Then we will explore the different types of motors utilized in electric cars, from permanent magnet motors to induction motors.

We will examine their unique characteristics, advantages, and limitations and provide insights into their operational principles and efficiency.

Next, we will delve into the role of the inverter, which acts as the brain of the motor drive system, converting DC power from the battery into AC power to drive the motor.

We will explore the complexities of inverter design, including its various control strategies, thermal management, and power electronics, and highlight its critical role in optimizing motor performance.

Furthermore, we will discuss the integration of motors and drive units in electric vehicles, including their placement, cooling systems, and overall system efficiency.

We will also examine the impact of motor and drive unit design on factors such as vehicle range, performance, and charging time and highlight the latest technological advancements in this field.

Finally, we will explore the prospects of motors and drive units for electric cars, including advancements in motor technology, improvements in power electronics, and emerging trends such as wireless charging and solid-state batteries. We will also discuss the challenges and opportunities associated with these technologies and their potential impact on the future of electric mobility.

Whether you’re an EV enthusiast, an automotive engineer, or simply curious about the inner workings of electric cars, this comprehensive article will provide a deep understanding of motors and drive units, shedding light on the cutting-edge technologies driving future transportation. So join us as we embark on a thrilling journey into the world of electric vehicle propulsion, uncovering the secrets behind the power that propels the future of mobility.

How do electric motors work?

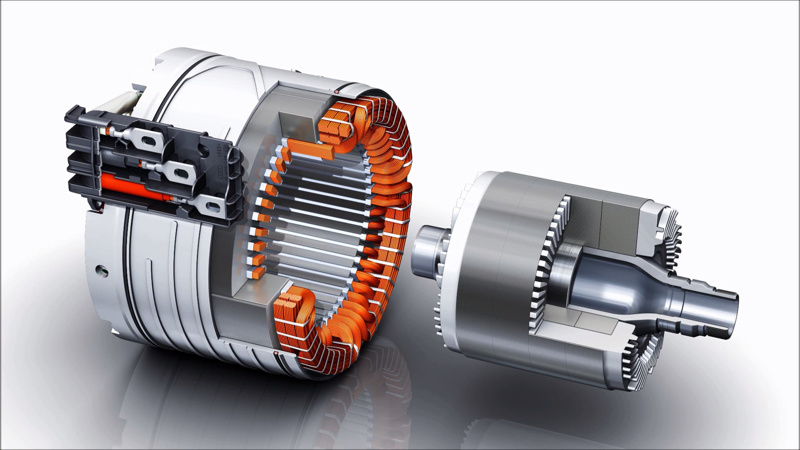

Even though there exist several types of electric motors, the principles are the same. Electric motors work based on the principles of electromagnetism. They consist of a stator and a rotor, with the stator being a stationary part and the rotor being a rotating part.

Stator & Rotor.

The stator contains coil windings that are connected to a power source, which generates an electric current that flows through the windings, creating a magnetic field.

The rotor, on the other hand, contains magnets or windings, and when the magnetic field generated by the stator interacts with the magnets or windings in the rotor, it creates a force that causes the rotor to rotate. This rotational motion is then transferred to the mechanical load, such as the wheels of a vehicle, which propels the vehicle forward.

The motor controller controls the direction and speed of the motor’s rotation by varying the current flowing through the stator windings, which alters the strength and orientation of the magnetic field. This technique allows precise motor performance control, including torque, speed, and power output.

Different types of electric motors, such as permanent magnet and induction motors, have varying designs and operational principles. Still, they all rely on the interaction between magnetic fields and electric currents to generate motion.

Induction motors

Induction motors, also known as asynchronous motors, are a type of electric motor that is widely used in electric vehicles (EVs) for their unique characteristics and advantages.

Permanent Magnet Synchronous motors

Synchronous motors are a type of electric motor that is also used in electric vehicles (EVs) for propulsion, but they operate differently from asynchronous motors. Synchronous motors require a physical connection between the rotor and the stator, typically through permanent magnets, which makes them distinct from asynchronous motors that rely on electromagnetic induction.

Wound-Rotor Synchronous Motor

A wound-rotor synchronous motor, also known as a slip-ring synchronous motor, is a type of electric motor that combines features of both synchronous motors and wound-rotor induction motors.

The Inverter

The inverter is a crucial electric vehicle (EV) drive unit component. It is responsible for converting the direct current (DC) electricity stored in the vehicle’s battery into alternating current (AC) electricity, which is then used to power the electric motor that drives the wheels of the EV.

Motor cooling

Cooling is an important aspect of electric motor design in electric vehicles (EVs) to ensure optimal performance, efficiency, and reliability.

Gears

Electric vehicles (EVs) typically use various types of gearboxes in their drive units, depending on the specific design and requirements of the car.

Motor setup

Electric vehicles (EVs) can use various motor setups depending on the specific design and requirements of the car. Some of the typical motor setups used in EVs include:

Single motor setup: In a single motor setup, a single electric motor is used to drive the vehicle. This motor can be either a permanent magnet synchronous motor (PMSM) or an asynchronous or induction motor (ASM). It drives either the front or rear wheels of the vehicle.

Dual motor setup: Two electric motors are used in a dual motor setup, typically one for each axle or wheel. This setup allows for more precise torque distribution between the front and rear wheels, enabling better traction control and improved performance, especially in all-wheel-drive (AWD) configurations. The motors can be PMSMs, WRSMs, ASMs, or a combination.

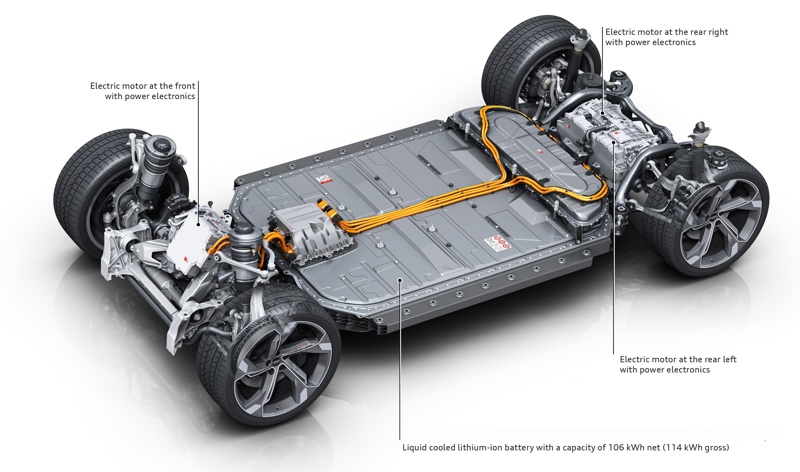

Tri-motor setup: A tri-motor setup is similar to a dual-motor design but with three electric motors instead of two. This setup is rare and used in high-performance models like Tesla Model S Plaid and Audi SQ8 e-tron. One advantage is the possibility of torque vectoring.

Tri-motor setup

Quad motor setup A quad motor setup has one motor for each wheel. Here are some of the advantages of having four motors in an EV

Precise traction control: Each motor can independently adjust the torque at each wheel, depending on the road conditions and the driver's input. This can improve the stability, handling, and safety of the vehicle, especially in off-road and snowy situations. For example, the Rivian R1S quad motor can use a feature called "tank turn" to spin on the spot by rotating the wheels on one side in one direction and the wheels on the other side in the opposite direction

Torque vectoring: Each motor can also vary the torque at each wheel to enhance the steering and cornering of the vehicle. This can reduce oversteer and understeer, common problems in conventional vehicles. Torque vectoring can also make the vehicle more agile and responsive and more fun to drive.

Some models with Quad motor setup is

Below, you see the Rivian R1T Quad motor do a tank turn with the quad motor setup.