Induction Motors

Induction motors, also known as asynchronous motors, are a type of electric motor that is widely used in electric vehicles (EVs) for their unique characteristics and advantages.

Asynchronous motors, also known as induction motors, are commonly used in electric vehicles (EVs) for propulsion. They are renowned for their simplicity, reliability, and efficiency, making them well-suited for automotive applications.

How It Works

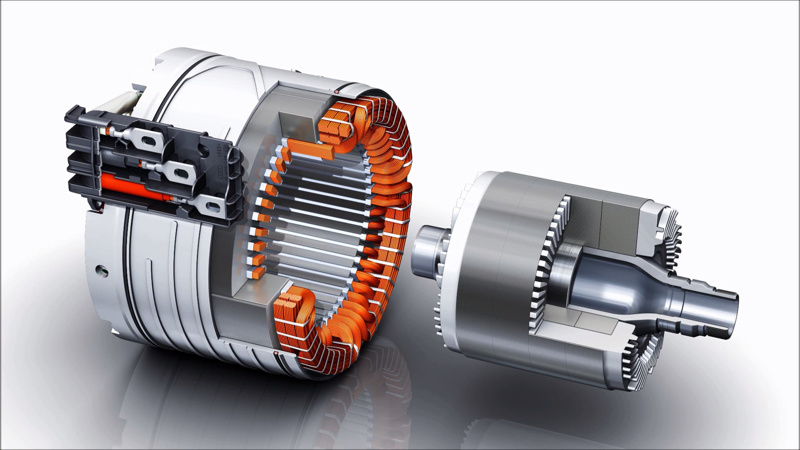

Audi Q8 e-tron induction motor stator

Induction motors operate based on the principle of electromagnetic induction. The stator winding is connected to an AC power supply, creating a rotating magnetic field. This field induces currents in the rotor winding, generating a magnetic field in the rotor. The interaction between the rotor’s magnetic field and the stator’s rotating magnetic field produces torque, driving the motor and the vehicle.

A key feature of asynchronous motors is that they do not require a physical connection between the rotor and the stator, unlike synchronous motors that use permanent magnets. Instead, they rely on electromagnetic induction to generate the rotating magnetic field that drives the rotor. This makes them inherently more robust and less prone to wear and tear, as there are no brushes or slip rings to maintain or replace.

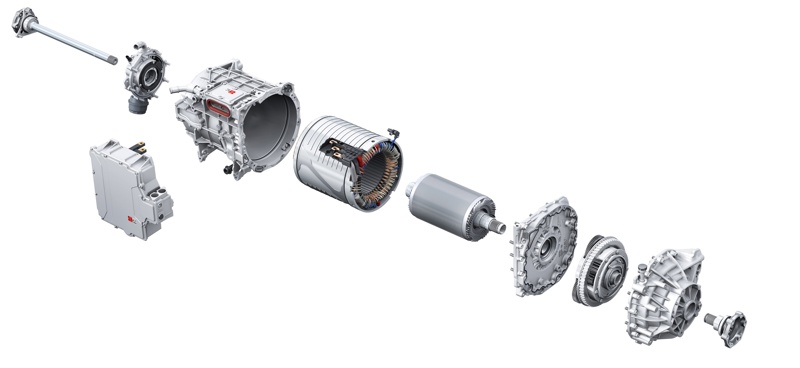

Asynchronous motors used in EVs are typically three-phase motors, meaning they have three sets of windings in the stator that are electrically separated by 120 degrees. This allows for smooth and continuous rotation of the motor without needing additional components, such as a gearbox, to convert the power from the battery to the wheels.

Audi Q8 e-tron induction motor

Types: There are two main types of induction motors used in EVs: squirrel cage rotor and wound rotor. Squirrel cage rotor induction motors are the most commonly used type in EVs due to their simple construction, high reliability, and low maintenance requirements. Wound rotor induction motors have a more complex construction with externally accessible rotor windings, allowing for better control of motor performance but may require additional maintenance.

Advantages

Induction motors offer several advantages for EV applications, including:

Ruggedness and Reliability: Induction motors are known for their robust construction and ability to withstand harsh operating conditions, making them highly reliable and durable in EV applications.

High Torque at Low Speed: Asynchronous motors can provide high torque at low speeds, which is crucial for EVs during startup and hill climbing. This torque capability is made possible by the rotor and stator design and the use of power electronics to control the motor’s performance.

Cost-effectiveness: Induction motors do not require permanent magnets, making them more cost-effective compared to other motor types, such as permanent magnet motors.

Low Drag When Rolling: When an EV is coasting or rolling without power, the electric motor can create a drag effect, often referred to as “motor drag” or “coasting drag.” This drag is caused by the electromagnetic forces within the motor, which can resist the rotor’s motion and create resistance against the vehicle’s movement.

Audi Q8 e-tron induction motor

In the case of induction motors, the rotor does not have any permanent magnets, and the drag from the motor is typically lower compared to permanent magnet motors. This is because induction motors rely on electromagnetic induction to generate the rotating magnetic field in the rotor, which induces current and creates magnetic forces that oppose the rotor’s motion. As a result, the motor drag in an induction motor is typically lower, and the vehicle can roll with less resistance when the motor is not actively powered.

Limitations

Induction motors also have some limitations in the context of EVs, including:

Lower Efficiency at High Speeds: Induction motors may have lower efficiency compared to some other motor types, such as permanent magnet motors, at high speeds, which can affect overall vehicle efficiency.

More Complex Control: Induction motors require complex control algorithms to achieve optimal performance, including control of motor speed, torque, and power factor, which can require sophisticated power electronics and control systems.

Higher Weight and Size: Induction motors may be larger and heavier compared to some other motor types, impacting vehicle weight and packaging considerations.

Most sold EVs globaly

Below, you find the top 10 most-sold EV models in the world. Click on the name for full info.