Cell formats

Several types of cell formats exist for battery cells used in electric vehicles.

Cylindrical housing

A cylindrical cell consists of sheet-like anodes, separators, and cathodes that are sandwiched, rolled up, and packed into a cylinder-shaped can. This form factor is the form factor that battery manufacturers have used for years in the market with battery sizes like AAA and AA used in electronics.

Tesla 4680 cylinder battery

One advantage is mechanical stability. The round shape of the battery distributes the internal pressure from side reactions over the cell circumference almost evenly. This stability allows the cell to tolerate higher internal pressure without deformation.

Another advantage is that it is possible to get a high throughput of cells from production lines.

Tesla is one of the few EV manufacturers that uses this. BMW will start using it in next generation.

There is three different sizes used

| Type | Size | Capacity |

| 18650 | 18 x 65mm | 2300mWh - 36000mWh |

| 21700 | 21 x 70mm | 4000mWh - 53000mWh |

| 4680 | 46 x 80mm | ~98000mWh |

Panasonic 18650, 21700 and 4680 batteries

Prismatic housing

Li-ion cells with prismatic housing consist of large sheets of anodes, cathodes, and separators sandwiched, rolled up, and pressed to fit into a hard-plastic or metallic housing in cubic form. The electrodes can also be assembled by layer stacking rather than jelly rolling.

Samsung prismatic cells

Parts of a prismatic cell’s electrode and separator sheets close to the container corners can experience more stress. This stress can damage electrode coating and lead to the non-uniform distribution of the electrolyte.

The cell box-like shape optimizes the available space when combining prismatic cells into packs.

Pouch housing

Pouch cells do not have a rigid enclosure like prismatic and cylinder cells and use a sealed flexible foil as the cell container.

This makes it the most efficient use of space and achieves a 90 to 95 percent packaging efficiency, the highest among battery packs, advantages of flexible size, and safety performance. Eliminating the metal enclosure reduces weight but the cell needs some alternative support in the battery compartment.

Swelling Pouch Cell Battery as a Result of Gas Generation During Charge and Discharge

The electrode and separator layers of a pouch cell are stacked rather than jelly-rolled. With pouch cells, the designer should allocate enough space for the cell swelling. A swelling of as much as 8% to 10% can occur after 500 cycles.

LG Chem pouch cell

Blade

Blade batteries are a type of lithium-ion battery that use a unique “blade” design for their battery cells. Unlike traditional cylindrical or prismatic battery cells, blade batteries are thin and flat, resembling the shape of a blade or a wafer.

The blade design of the battery cell allows for a more compact and efficient battery pack, as the cells can be tightly packed together to reduce the size and weight of the battery pack. This also provides better heat dissipation, as the flat shape of the cells allows for more surface area to come in contact with the cooling system.

Blade batteries are primarily produced by the Chinese battery manufacturer BYD.

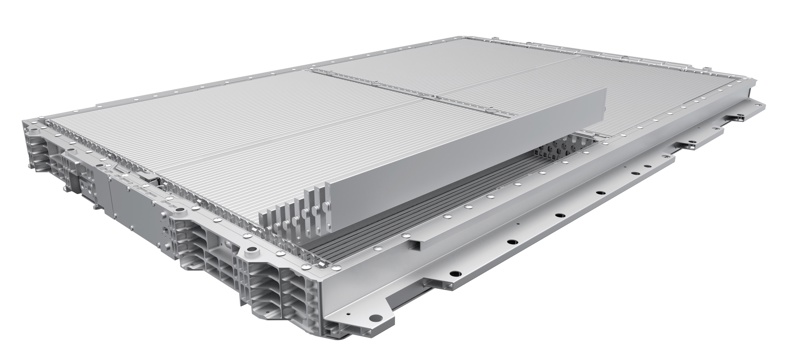

BYD Blade Battery

One of the key safety features of blade batteries is the use of a ceramic separator between the anode and cathode layers of the cell. This ceramic separator is more resistant to thermal runaway and provides better protection against internal short circuits, reducing the risk of battery fires and explosions.

Most sold EVs globaly

Below, you find the top 10 most-sold EV models in the world. Click on the name for full info.