Brakes

The braking system is crucial for the safety of passengers and other road users, as well as the longevity of the vehicle. This article explores the different types of EV brakes, including steel disc brakes, carbide brakes, ceramic brakes, and drum brakes. It also covers details about blended brakes.

Last modified: Dec 31, 2024Due to the regenerative braking capability of electric motors in EVs, traditional friction brakes may be used less frequently. This results in reduced wear on brake pads and discs compared to ICE vehicles. However, it's important to note that all EVs still have traditional friction brakes as a backup or supplementary system for hard braking or emergencies. The use of regenerative braking and standard friction brakes in EVs depends on the specific design and configuration of the vehicle, as well as the preferences and driving habits of the driver.

Disc Brakes

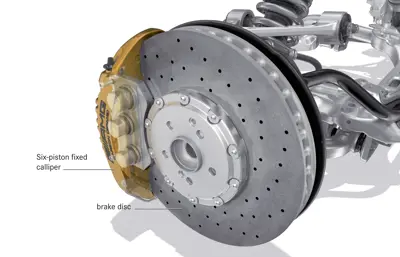

Disc brakes, also known as "disk brakes," are automobile braking systems that use friction to slow down or stop the vehicle. They consist of several components, including the brake rotor, brake caliper, brake pads, and sometimes brake lines and a brake master cylinder.

The brake rotor is a flat, circular metal disc attached to the wheel hub that rotates with the wheel. The brake caliper houses the brake pads and is positioned over the brake rotor. The brake pads, typically made of high-friction material, are positioned on each side of the rotor. When the driver applies the brakes, hydraulic pressure pushes the brake pads against the rotor, creating friction and causing the vehicle to slow down or stop. Pistons are used to push the brake pads, and more powerful brakes have more pistons.

Disc brakes are known for their superior stopping power and heat dissipation compared to other types of braking systems, such as drum brakes. They are more effective in dissipating heat generated during braking, which helps to reduce brake fade—a phenomenon where braking performance decreases due to excessive heat buildup. Disc brakes also provide more consistent and linear braking performance, allowing for better modulation and control.

Due to their performance advantages, disc brakes have become the standard in most modern vehicles. However, some older or smaller vehicles may still use drum brakes in certain applications. Disc brakes can be found on both the front and rear wheels of many vehicles and are a critical safety feature that plays a crucial role in the overall braking system of a vehicle.

Brake discs, or rotors, can be made of different materials depending on the specific application and performance requirements.

Cast-iron/Steel Disc Brakes

Steel disc brakes are the most common type used in automobiles, including EVs. They work by using friction between the brake pads and the brake disc to slow down or stop the vehicle. The brake pads are made of a composite material that includes steel fibers, carbon fibers, and ceramic materials. The brake disc is usually made of cast iron.

One of the main advantages of steel disc brakes is their reliability and durability. They are also relatively inexpensive compared to other types of brakes. However, they can generate a lot of heat, which can lead to brake fade and reduced performance. Additionally, they can create a lot of brake dust, which can be harmful to the environment.

Carbid Brakes

Carbid brakes are a type of high-performance brake used in some EVs. They are made of a composite material that includes carbon fibers and silicon carbide. This material has a high resistance to heat and wear, making it ideal for high-performance applications.

One of the main advantages of carbid brakes is their ability to withstand high temperatures without losing effectiveness. They are also more resistant to wear than steel disc brakes, which means they have a longer lifespan. However, they are more expensive than steel disc brakes, which can make them less practical for some applications.

Ceramic Brakes

Ceramic brakes, also known as ceramic composite brakes or carbon ceramic brakes, are used in electric vehicles (EVs) and high-performance vehicles. They are designed to provide superior braking performance, particularly under high-speed and high-temperature conditions.

Ceramic brakes are made from a composite material that consists of ceramic fibers, such as silicon carbide (SiC), embedded in a matrix of carbon or silicon. This combination gives ceramic brakes their unique properties, including high thermal conductivity, low thermal expansion, and excellent wear resistance.

One of the main advantages of ceramic brakes in EVs is their ability to handle high temperatures without experiencing brake fade. Since EVs often have regenerative braking systems that rely heavily on the brakes for energy recovery, ceramic brakes can handle the heat generated during aggressive regenerative braking without significant loss of performance.

In addition to their high-temperature performance, ceramic brakes offer several other benefits for EVs. They are typically lighter than traditional steel brakes, which can help reduce the overall weight of the vehicle and improve efficiency. Ceramic brakes are also known for their exceptional durability and longevity, reducing maintenance costs over time.

However, ceramic brakes are significantly more expensive to manufacture than traditional steel brakes, making them a luxury option for high-end EVs or performance vehicles. Additionally, ceramic brakes can be more brittle and may not perform as well in extremely cold temperatures, which could limit their effectiveness in certain climates.

Overall, ceramic brakes are a high-performance option for EVs that offer excellent thermal resistance, durability, and weight reduction benefits. However, their higher cost and potential limitations in extreme cold temperatures should be considered when evaluating their suitability for a particular EV application.

Floating or Fixed Brake Caliper?

The brake caliper can be either floating or fixed.

Floating Brake Caliper

A floating brake caliper, also known as a sliding caliper or single-piston caliper, has a piston(s) on one side of the brake rotor, while the other side "floats" or slides on guide pins or bolts. When the brakes are applied, hydraulic pressure pushes the piston(s) against the brake pads, which then clamp onto the rotor, creating friction and slowing down the vehicle. The sliding side of the caliper moves inward, guided by the pins or bolts, to allow the brake pads to contact the rotor. This design allows the caliper to self-center and adjust for variations in rotor thickness and wear.

Fixed Brake Caliper

A fixed brake caliper, also known as an opposed-piston caliper or multi-piston caliper, has pistons on both sides of the brake rotor. The caliper is mounted rigidly to the vehicle's suspension or axle, and both sets of pistons apply pressure on the brake pads simultaneously to clamp onto the rotor when the brakes are applied. Fixed calipers typically have multiple pistons on each side of the caliper, arranged in an opposed configuration, which helps to evenly distribute the clamping force on the brake pads and provide consistent braking performance.

Key differences between floating and fixed brake calipers include:

- Construction: Floating calipers typically have a single piston on one side of the caliper, while fixed calipers have multiple pistons on both sides.

- Mounting: Floating calipers "float" or slide on guide pins or bolts, allowing for self-centering and accommodating rotor wear, while fixed calipers are rigidly mounted to the vehicle's suspension or axle.

- Number of pistons: Floating calipers typically have one piston per caliper, while fixed calipers may have multiple pistons per caliper, often in an opposed configuration.

- Brake pad wear: Floating calipers may wear brake pads unevenly due to their sliding design, while fixed calipers tend to wear brake pads more evenly.

- Brake performance: Fixed calipers are generally known for providing higher performance and better braking, especially in high-performance or heavy-duty applications, due to their increased clamping force and piston arrangement.

Both floating and fixed calipers are used in disc brake systems and have their advantages and disadvantages depending on the specific application and performance requirements. The choice between floating and fixed calipers is typically determined by factors such as vehicle type, performance requirements, cost considerations, and manufacturer preferences. Many models have fixed calipers on the front axle and floating calipers on the rear axle.

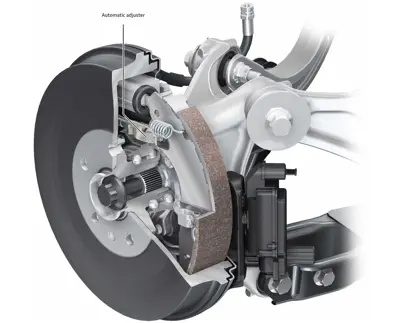

Drum Brakes

Drum brakes are used in some EVs, especially in the rear wheels. They work by using friction between the brake shoes and the inside of the brake drum to slow down or stop the vehicle. The brake shoes are made of a composite material that includes steel fibers, carbon fibers, and ceramic materials. The brake drum is usually made of cast iron.

One of the main advantages of drum brakes is their simplicity and low cost. They are also very reliable and have a long lifespan. However, they are less effective than other types of brakes, especially at high speeds. Additionally, they can generate a lot of heat, which can lead to brake fade and reduced performance.

Different Sizes

The size of the brakes used in EVs can vary depending on the vehicle's weight, size, and intended use. Generally, larger brakes are needed for heavier vehicles and for vehicles used in high-performance applications.

The size of the brakes is typically determined by the diameter of the brake disc or the brake drum. The larger the diameter, the more surface area there is for the brake pads or shoes to grip, which means more braking force can be applied.

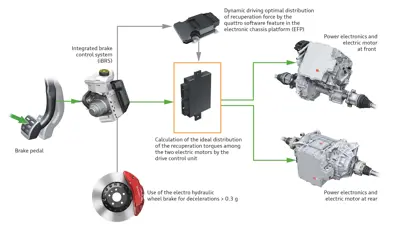

Brake-by-wire Technology and Blended Brakes

Brake-by-wire technology is an innovative system used in electric vehicles (EVs) that allows for seamless integration of regenerative braking with traditional friction braking. Regenerative braking is a process in which the electric motor of an EV acts as a generator, converting the kinetic energy of the vehicle's motion into electrical energy, which is then stored in the battery for later use. Brake-by-wire technology enables the vehicle to automatically switch between regenerative braking and friction braking, depending on various factors such as vehicle speed, battery state of charge, and driver inputs.

The basic components of a brake-by-wire system include sensors, actuators, and an electronic control unit (ECU) that monitors and controls the braking system. Sensors, such as wheel speed sensors, brake pedal position sensors, and battery state of charge sensors, gather data on the vehicle's speed, acceleration, braking, and battery status. Actuators, such as electric motors or solenoids, control the application of braking force to the wheels. The ECU processes the sensor data and determines the appropriate amount of braking force to be applied, either through regenerative braking or friction braking, and commands the actuators accordingly.

One of the key advantages of brake-by-wire technology is its ability to blend regenerative braking with friction braking in a seamless and efficient manner. When the vehicle is decelerating or coming to a stop, the brake-by-wire system can first engage regenerative braking, which captures the kinetic energy of the vehicle and converts it into electrical energy to charge the battery. This helps to extend the vehicle's driving range and increase overall energy efficiency. If more braking force is needed beyond what regenerative braking can provide, the system can then gradually transition to friction braking, where the brake pads are applied to the wheels to provide additional stopping power.

Another advantage of brake-by-wire technology is its flexibility and adaptability. The system can be programmed to adjust the regenerative braking level based on various factors, such as driver preferences, road conditions, and battery state of charge. For example, in situations where the battery is fully charged or the road conditions are slippery, the system can increase the use of regenerative braking to maximize energy recovery and improve vehicle stability.

Furthermore, brake-by-wire technology allows for advanced braking features, such as regenerative braking in corners, which can help improve vehicle handling and stability during cornering maneuvers. By independently controlling the braking force applied to each wheel, the system can optimize the regenerative braking in each wheel to provide better traction and stability during turns.

However, brake-by-wire technology also comes with some potential challenges. One of the main concerns is the reliability and safety of the system, as it relies heavily on electronic components and software. Appropriate fail-safe measures, redundancy, and rigorous testing are essential to ensure the safe operation of the system. Additionally, driver education and training are crucial to help drivers understand the unique characteristics of brake-by-wire systems and how to operate them effectively.

In summary, brake-by-wire technology is an advanced system that allows for seamless integration of regenerative and friction braking in EVs. It offers improved energy efficiency, driving range, and advanced braking features, but also requires careful consideration of reliability, safety, and driver education. As technology continues to evolve, brake-by-wire systems are expected to play a significant role in the future of EV braking systems, contributing to more efficient and sustainable transportation.

In our EVKX database, you can search for models with different types of brakes.